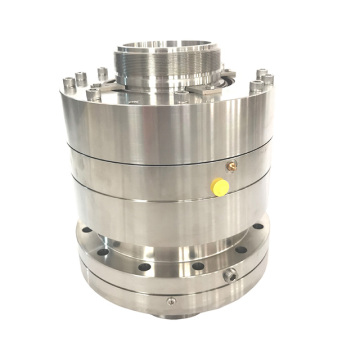

Customized Double Balanced Mechanical Seal

Product Description

Products Description

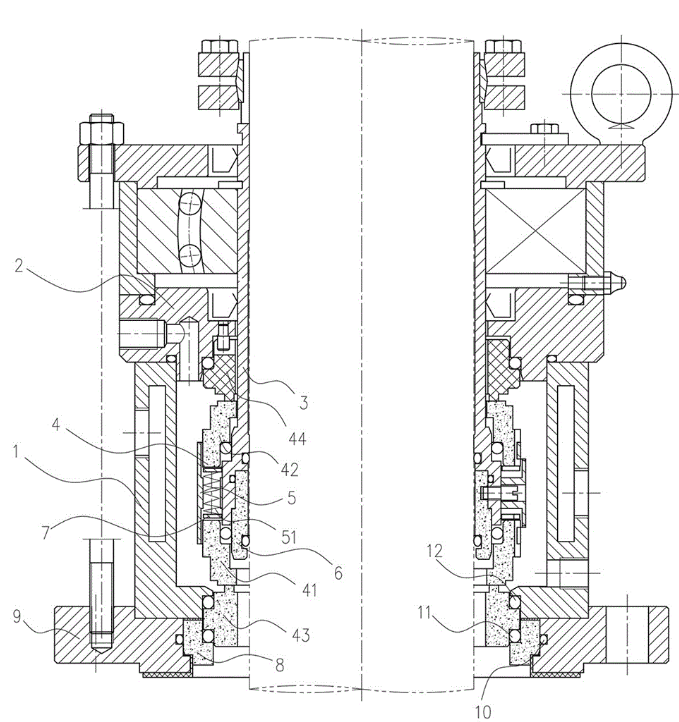

Compared with single-end mechanical seal, double-end mechanical seal has good sealing performance and is suitable for sealing under the conditions of strong corrosion, high temperature, with suspended particles and fiber medium, gas medium, inflammable and explosive, volatile low viscosity medium and high vacuum.

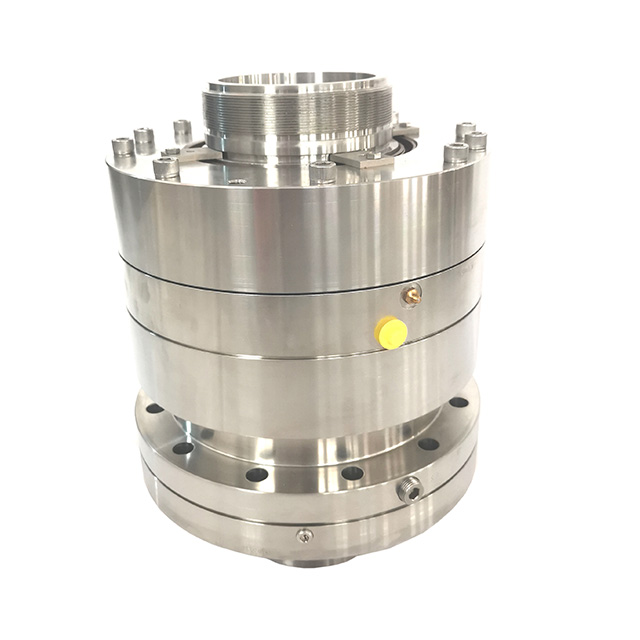

COMBINATION OF MATERIALS

Housing: Stainless Steel

Product-wetted parts: SS304, SS316, Hastelloy, Titanium, other special materials

Seal rings: Carbon, Silicon Carbide, Tungsten Carbide etc.

O-rings: FKM , EPDM, FFKM etc.

Applications Scenario

Main Characteristics

➤Low cooling water consumption:Cooling water is only used for back cooling, which is significantly lower than the original cooling water consumption on site

➤Good sealing effect:Double-end mechanical seal has two seals. If the first seal fails, the second seal can still be sealed to prevent leakage

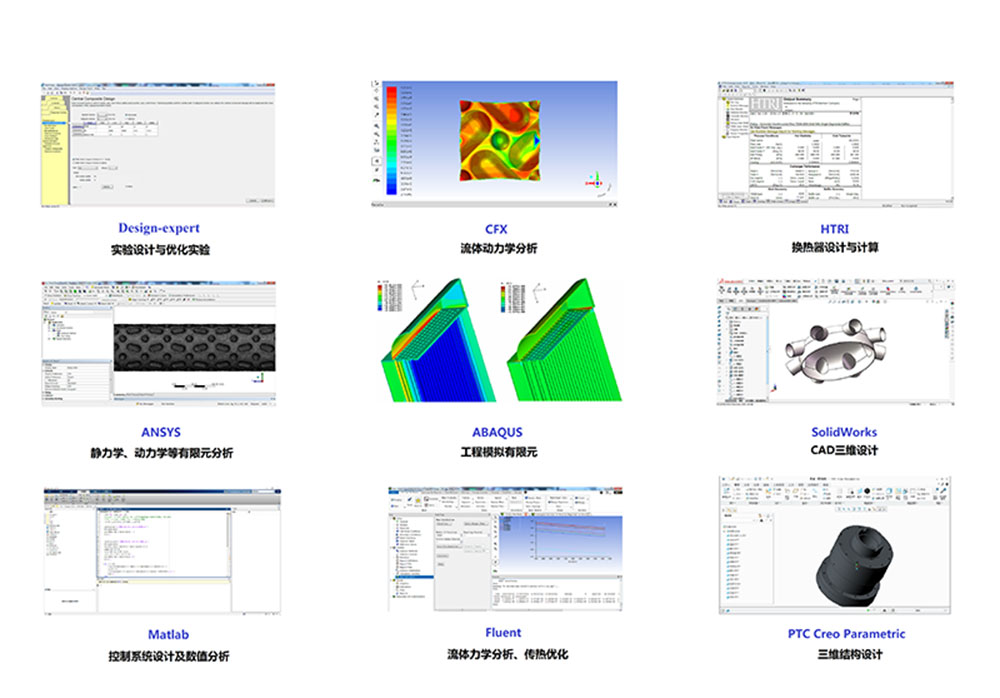

Design / Calculation Software

1. Multifunctional “Three in One” (filtering, washing and drying)

3. Sterile double-cone dryer

4. Rake Vacuum Dryer /Paddle Vacuum Dryer

5. Plate-fin Heat Exchanger

➤Our advantage

Equipment made of anti-corrosion materials includes: anti-corrosion lining plastic/ PTFE/ enamel,

2.Customized Design: Double-Cone in 20L-20m³

Rake Dryer (with mechanical seal) in 16 m³

DN300-DN600 “Three in One”

3.Design/Calculation Software

➤Scope of business

1. On-site Inspection

2.Technical Innovation Plan for Equipment Technical Improvement Plan for Equipment’s Structure Optimization Fast and Effective Solution to Equipment Malfunctions Highly Efficient and Precise On-site Construction Service Commitment to a Deadline in Customization A Full Range of long-term on-site technical maintenance service

3. Maintenance

4. Technical Solutions

5.On-site Testing and Training

6. Spare Parts

Product Categories : Metal Bellows and Mechanical Seal